Cryogenic Valves

Flowcen Global supplies cryogenic valves, including globe, gate, ball, and check valves for LNG, LOX, and industrial gas projects. Built in India and trusted in Middle East and African markets, our valves are designed for reliable low-temperature service. Get a quote for cryogenic valves today.

Cryogenic Valves for LNG and LOX – Flowcen Global

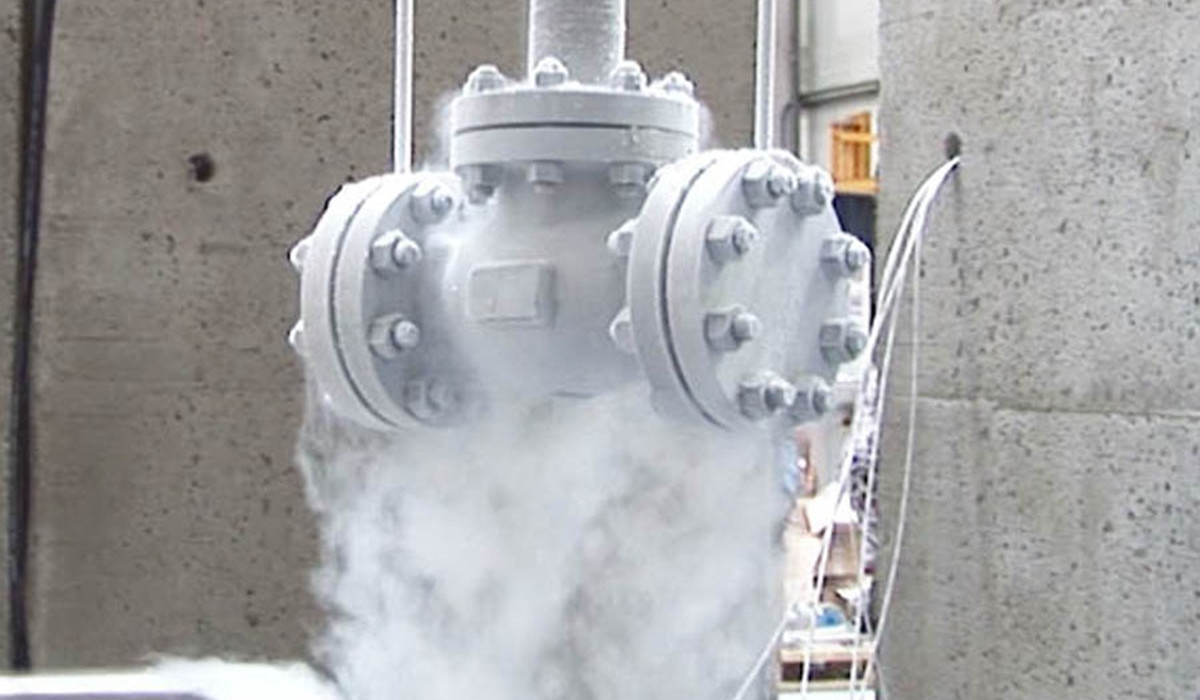

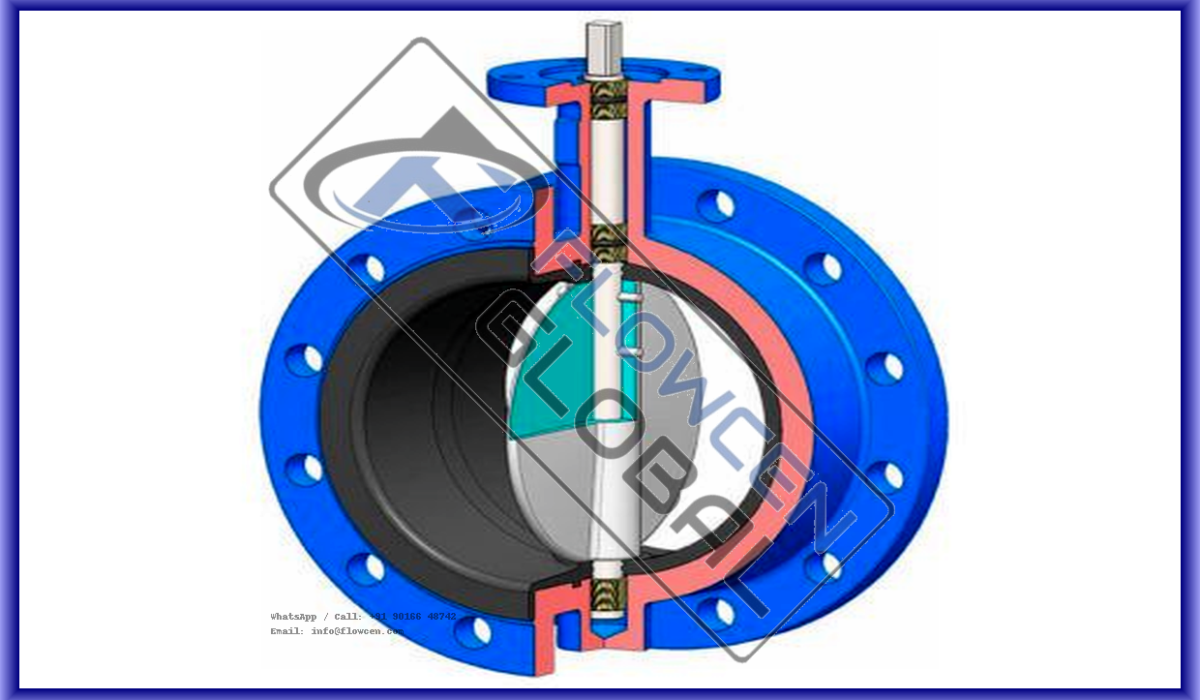

Cryogenic valves are critical for handling ultra-low temperature fluids like LNG, liquid oxygen (LOX), liquid nitrogen (LIN), helium, and other industrial gases. Regular valves often fail under such conditions due to brittleness or leakage. Flowcen Global, a leading manufacturer from India, delivers Cryogenic Globe, Gate, Ball, Check, and Butterfly Valves engineered to perform reliably at temperatures as low as -196°C.

Trusted by Global Projects

Flowcen Global is known for precision engineering and proven performance in high-profile projects. We have successfully supplied pressure relief valves for L&T’s projects in Qatar, earning trust from EPC contractors, OEMs, and industrial end-users. Our cryogenic solutions are widely used in LOX storage, LNG transfer, and industrial gas distribution systems.

Our Cryogenic Valve Range

Cryogenic Globe Valves – For accurate throttling and shut-off.

Cryogenic Gate Valves – Full-bore design minimizing pressure loss.

Cryogenic Ball Valves – Bubble-tight sealing and fast operation.

Cryogenic Check Valves – Prevent reverse flow in pipelines.

Cryogenic Butterfly Valves – Lightweight solutions for larger diameters.

Industries and Regions We Serve

Our valves are used across LNG terminals and storage units in India, Qatar, UAE, and Kuwait. We serve liquid oxygen (LOX) and industrial gas plants in Saudi Arabia and Oman, as well as air separation and petrochemical facilities in Kenya, Nigeria, and South Africa. Cryogenic tanker systems and cold box applications across Southeast Asia also rely on our engineered solutions.

Why Flowcen Global?

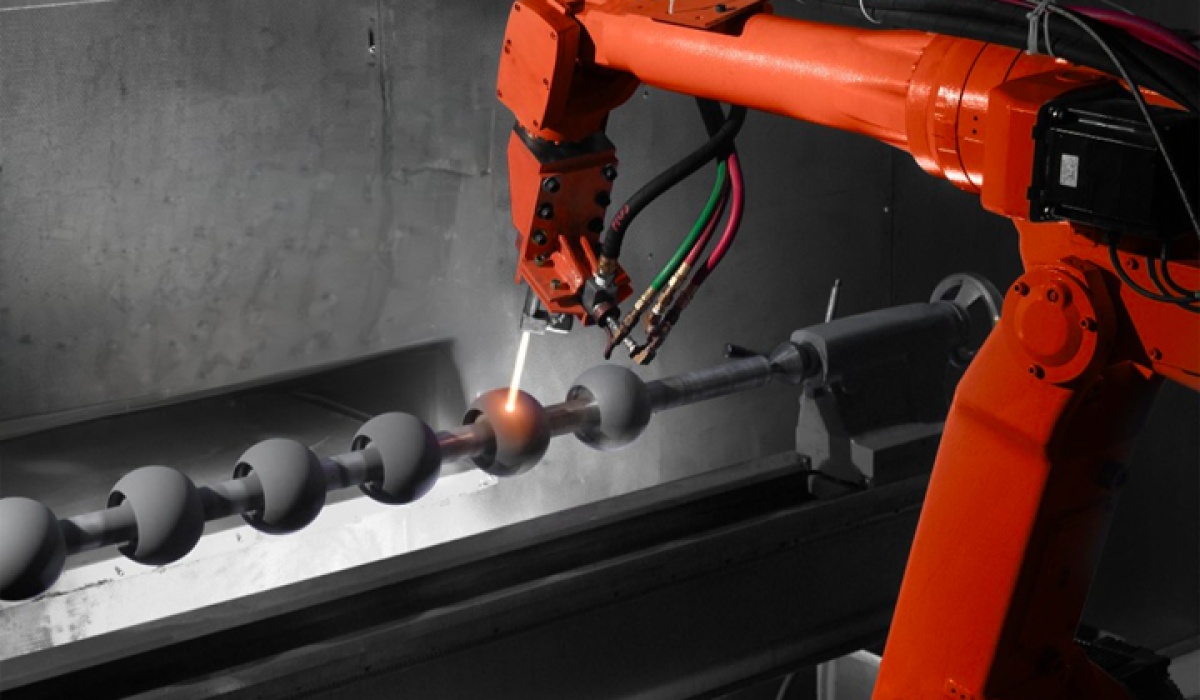

We manufacture valves using high-quality stainless steel and cryogenic-grade alloys. Every product is tested to BS 6364 and API 598 standards. We offer flanged, butt weld, and socket weld connections, as well as manual, gear-operated, or automated actuation options. All valves are packaged with export-ready documentation and meet international project requirements.

Get Your Project Valves Today

For LNG, LOX, or industrial gas projects, Flowcen Global delivers engineered reliability, competitive pricing, and responsive service.

Call / WhatsApp: +91 90166 48742

Email: info@flowcen.com

-(1).png)